How Does a Sump Pump Float Work?

Sump pumps are set off automatically once the water level in the sump pit gets to a predetermined height. A homeowner can calibrate the pump to start at any depth they wish by adjusting the float device of the sump pump.

Water runoff and/ or seeping water is collected inside the sum pit. As the water gathers, a float rises as the water level rises. The float has control of an on/ off switch for the pump. Once the float rises to a predetermined height, the pump turns on. The pump continues to function until the float falls low enough to disconnect the switch. The pump is inactive once more until the water level increases again.

Types of Sump Pump Floats

Different types of floats are used by different types of sump pumps. Pedestal pumps will typically have a bulb type float connected to a metal rod that turns on the pump motor’s switch. Other types of pumps utilize floats attached to arms that will raise and lower as the water level rises and lowers. A tethered float is a float that is attached to the pump utilizing a tethering mechanism.

Old Sump Pump Float Working Principle

When the water level rises, the float will rise too. As the float rises the tether steadily releases. The tether is predetermined to start the pump when a specific amount of tether gets released. When the water levels lower, the tether becomes loose and the float falls back to its starting position.

New Sump Pump Float Working Principle

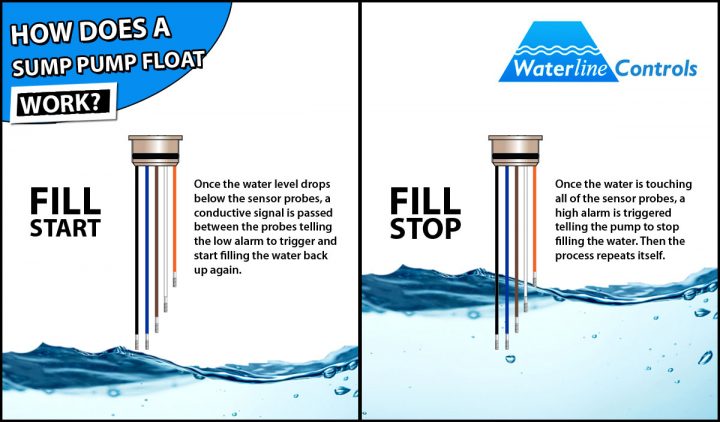

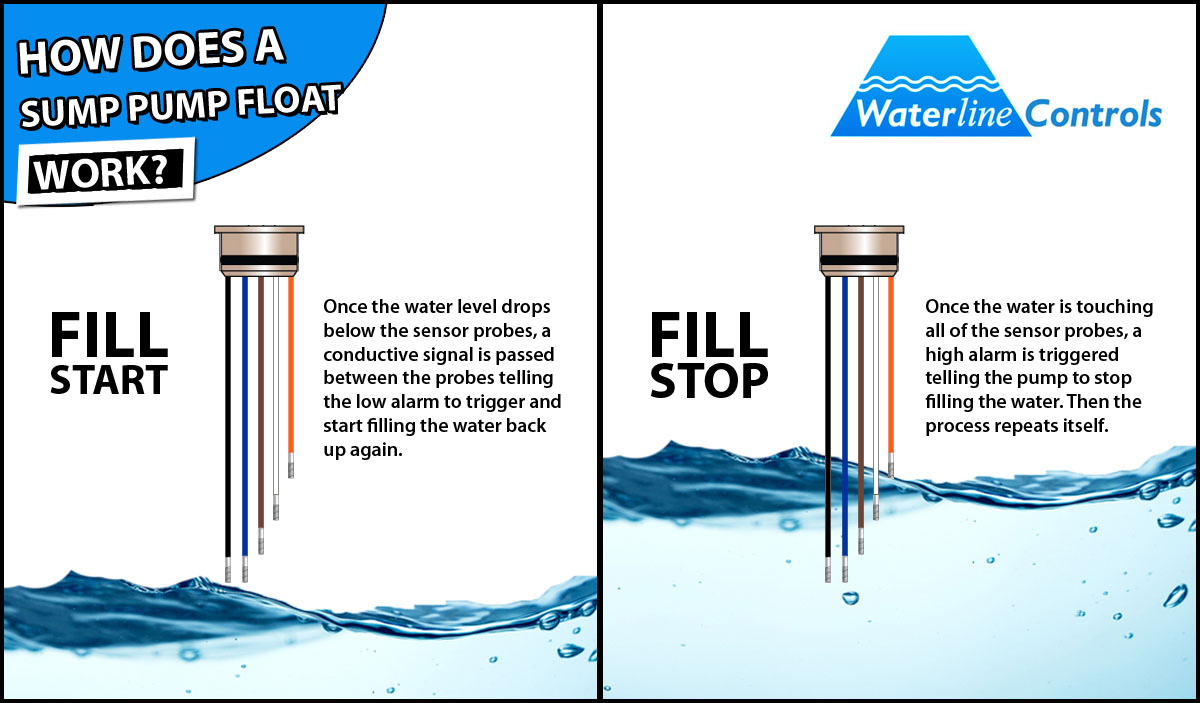

Float switches and water level controls typically start out open, meaning there are no alarms that are required to be activated since the water level is at its lowest.

- When the cooling tower stops using the water for its industrial operations, the water level starts to rise. No alarms have been activated up to this point.

- When the water level reaches the probes, a signal is transferred between the probes informing the high alarm to activate.

- When the high alarm is activated it can be programmed to tell the fill to stop filling up the water.

- Finally, when the water reached the predetermined limit, the fill stop kicks in and the process starts all over again.

With correct maintenance, your cooling tower float switches could last for years of operating. A lot of float switch failures typically occur due to degrading, wearing out, or fouling. Cooling tower coatings can safeguard the storage tanks, but what is safeguarding the float switches? Our water level controls can replace your old float switches once and for all and won’t degrade, wear out, or foul, because of any water quality.

Why Choose Water Line Controls

All of our water level controls and water level control systems are assembled right here in the U.S.A. where we monitor every step of the process. The are many reasons to choose Waterline Controls™ for all of your float switch and water level controller needs include:

SIMPLE DESIGN

No moving parts or mechanical floats to break or rust!

BEST TECH SUPPORT

No runaround, no guessing, no stupid answers. You’ll talk to the guy who’s been designing and installing these units for over 20 years.

BUILT TO LAST

Makes it easy to integrate with existing Building Management Systems and has an expected useful life of 15 years.

TOUCH TO TEST

One push of the button starts a complete validation cycle to ensure all systems are working properly.

RELIABLE & ACCURATE

Will not foul, plate, or deteriorate regardless of water quality.